05 on the diameter during a roughing pass, and no more than. When cutting on the OD cuts should take off no more than. Note: Refer to the speeds and feeds chart on the mindworks website ( ), and remember to differentiate between carbide and high speed steel cutting tools. Now you will select your speeds and feeds. Next we will face the part: Under toolpaths, select lathe toolpaths and then face. To your personal folder or other media (NOT the 10)īefore continuing the part should be saved same location as the tutorial). If you have any issues with this please make sure that you have your part oriented correctly. Now that the stock has been defined it is important to make sure that it encompasses the entire part and is directed along the correct axis. The machine will know only where the actual zero origin is so it is important to write down the relationship your origin has to the face of the part as well as the diameter of your stock. Machining Note: At this point you will need to enter coordinates for the lathe tools that allow you to remove material. Ĭlick on the properties under the stock setup area and left spindle setup. Expand the properties menu and click on stock setup. Under the tool paths tab on the left in the design tree, you will notice that some new items have appeared. This allows the final code to be posted to the HAAS CNC Lathe.

Note: If the HAAS CNC Lathe is not an option select Manage List, HAAS Lathe, and then Add to add it to the list of machines. To do this click Machine Type (found on the top toolbar), Mill, and select the HAAS CNC Lathe. 05 inches from the origin to allow for facing of the stock.īefore starting the tool paths, define the machine that you will be using. In this view the part should be oriented as you would see it on the lathe, with the face of the part.

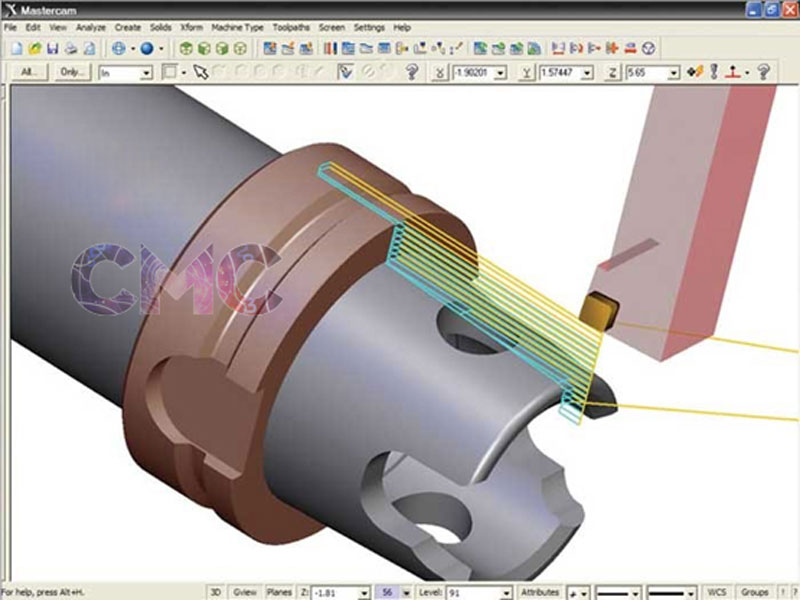

Make sure that the part is oriented properly click on the Top View. (refer to Mill Tutorial for object orientations)įor a more visual representation of the origin and the HAAS axis press F9. Open the file in SolidWorks and select the wireframe option and saveīe sure to check the “IGES wireframe” option.Īlign the part to a usable orientation, in order to do this we want the part to be facing right from a top view with the axis of rotation along the X-Axis. HAAS Lathe Tutorial (Print this tutorial out and follow step-by-step)Īfter reading the Mastercam X5 HAAS mill tutorial and finishing it to receive the basics.

0 kommentar(er)

0 kommentar(er)